+86 156 9019 9025 (WeChat & WhatsApp)

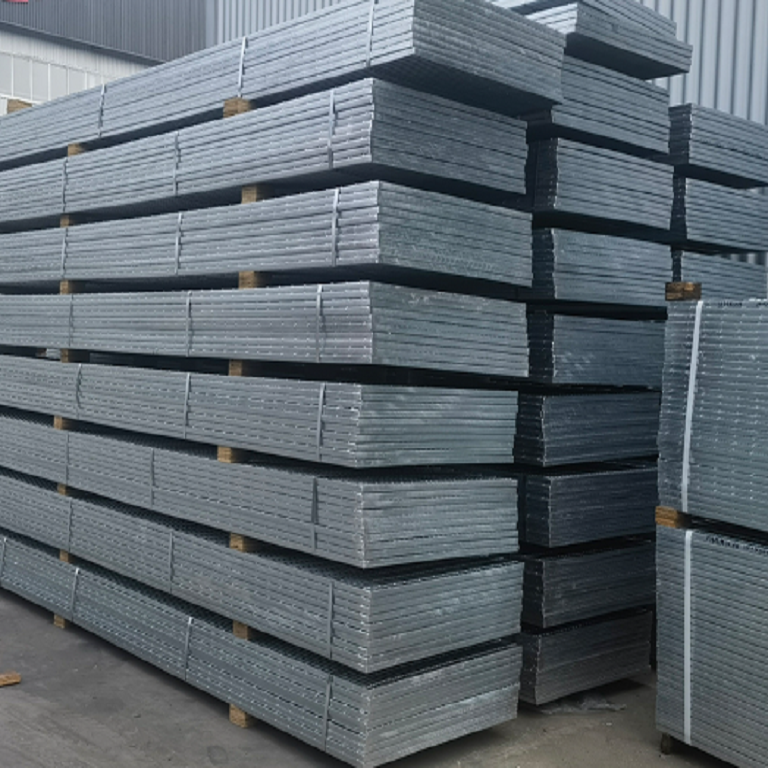

Standard Steel Grating provides a durable, versatile, and cost-effective solution for industrial, commercial, and architectural projects. If you are looking for reliable Standard Steel Grating that offers strength, easy installation, and long-lasting performance, Shunbo delivers high-quality options to meet your needs. With widespread use in factories, walkways, platforms, and drainage systems, standard steel grating combines practicality with safety, making it an essential component in modern construction and infrastructure projects.

Standard steel grating is a metal flooring solution composed of longitudinal bearing bars welded or pressed to cross bars, forming a grid structure. It is designed to provide high strength, good drainage, and excellent slip resistance. Typical features include corrosion-resistant coatings, customizable sizes, and load-bearing capacity suitable for industrial and commercial environments.

Standard steel grating is widely used in walkways, stair treads, platforms, drainage covers, and mezzanines. Its open grid design allows water, debris, and air to pass through, reducing maintenance while enhancing safety in high-traffic areas.

Standard steel grating comes in different load classes to suit various applications:

Light-Duty: Supports pedestrian traffic such as walkways and stair treads with safe load limits up to 300kg/m², making it ideal for metal grating floors in retail or office spaces.

Heavy-Duty: Handles vehicle and equipment loads on industrial platforms, road safety grating, and steel bar grating barriers with capacities exceeding 5,000kg/m².

Standard steel gratings, also known as Open Steel Grating, usually have a length ranging from 1000mm to 7500mm and a width ranging from 993mm to 1000mm. Bearing bars range from 20×3mm to 150×10mm.

Welded Grating: Bars are welded at intersections for maximum strength and stability.

Press-Locked Grating: Bars are pressed together, providing a cost-effective option with moderate strength.

Swage-Locked Grating: Combines mechanical locking with light welding for enhanced flexibility and safety.

For high-traffic areas or challenging conditions, heavy-duty gratings and anti-slip designs improve safety and durability. Outdoor gratings often feature hot-dip galvanization to resist weathering.

Heavy-duty grating offers higher load capacity and thicker bars, suitable for industrial floors carrying vehicles or heavy machinery. Standard steel grating is ideal for pedestrian areas and moderate loads, balancing cost and performance.

Stainless steel grating excels in corrosive environments and requires minimal maintenance, whereas standard carbon steel or galvanized options are more budget-friendly and sufficient for general use.

Standard Steel Grating: Affordable, versatile, easy to install; may require coating for corrosion protection.

Heavy Duty: Extremely strong; higher cost and weight.

Stainless Steel: Corrosion-resistant; premium price.

The cost of standard steel grating ranges from $25 to $70 per square meter, depending on material, size, and finish. Galvanized and stainless options typically command higher prices.

Price is influenced by material type, bar thickness, panel size, finish, and customization. Bulk orders often reduce unit costs.

Choosing a reputable supplier ensures quality and compliance with safety standards. Shunbo is known for high-quality products, timely delivery, and professional support.

Measure and cut panels to fit the area.

Secure bearing bars to support structure using clamps or welding.

Align panels evenly and fasten edges to prevent movement.

Apply protective coatings if necessary.

Regularly inspect for corrosion, loose fasteners, or structural damage. Clean debris to maintain drainage and prevent slip hazards.

Warped or damaged panels should be replaced promptly. Ensure load requirements are not exceeded to prevent bending or failure.

Galvanized or stainless steel is recommended for outdoor applications, while standard carbon steel suffices for indoor areas with minimal exposure to moisture.

Heavy-duty or welded options are preferred for industrial zones with vehicle traffic. Standard grating works well in commercial settings such as walkways, stairs, or drainage covers.

Manufacturers can provide tailored bar spacing, thickness, and surface treatments to match project specifications.

How long does standard steel grating last?

With proper maintenance, galvanized or coated steel grating can last 15–30 years.

Can standard steel grating be cut on-site?

Yes, using angle grinders or specialized cutting tools, but safety precautions must be followed.

What is the difference between press-locked and welded grating?

Welded grating is stronger and suited for heavy loads, while press-locked is more economical for moderate applications.

Standard steel grating is a practical, versatile, and reliable flooring and platform solution for various industrial and commercial projects. By selecting the right material, type, and supplier, you can ensure durability, safety, and cost-efficiency. For high-quality options, professional support, and customized solutions, Shunbo provides industry-leading products.

Previous

None

OTHER NEWS

Aluminum grating is a versatile and highly durable material used across industrial, commercial, and architectural applications. Known for its lightweight nature and superior corrosion resistance, aluminum grating offers a wide range of benefits that make it a popular choice in environments that demand strength, durability, and minimal maintenance.

How to Choose the Right Steel Grating? Learn about the different types and their benefits

Steel grating is a structural material widely used in industry, construction, municipal administration and other fields. Different types of steel grating have their own characteristics in terms of strength, corrosion resistance, load-bearing capacity and aesthetics.

HOT-SALE PRODUCT